Peliou New Materials Technology Co.,LTD

The stability of a mobile crane is non-negotiable. Every successful lift hinges on the crane's ability to remain perfectly level and secure, transferring immense loads safely into the ground. While the crane itself is a marvel of engineering, its stabili

The stability of a mobile crane is non-negotiable. Every successful lift hinges on the crane's ability to remain perfectly level and secure, transferring immense loads safely into the ground. While the crane itself is a marvel of engineering, its stability entirely depends on the often-overlooked interface between the outrigger beam and the ground: the crane outrigger pad. The design of these pads is not a matter of simple lumber planks; it is a critical engineering discipline that directly impacts safety and performance on the job site.

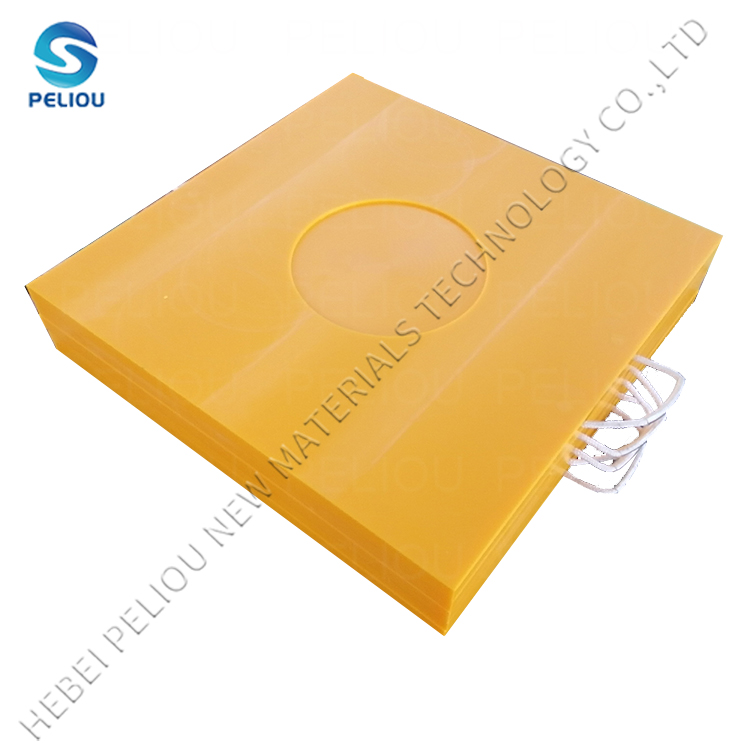

The core function of a crane outrigger pad is to distribute the colossal pressure exerted by the outrigger foot over a much larger surface area. Without a properly designed pad, the outrigger can sink into asphalt, crack concrete, or become unstable on soft soil, leading to a catastrophic shift in the crane's center of gravity. A well-engineered crane outrigger pad is calculated to handle the specific ground-bearing pressure of the site, preventing dangerous sinkage and ensuring a solid foundation. This is why modern pads are constructed from high-strength, composite materials like ultra-high-molecular-weight polyethylene (UHMW-PE) or reinforced steel, offering superior strength-to-weight ratios compared to traditional wood.

Beyond just preventing sinkage, intelligent crane outrigger pad design incorporates features that enhance safety and efficiency. Many modern pads include textured, non-slip surfaces on both sides to prevent shifting between the outrigger foot and the ground. Integrated handles and lightweight materials make them easier for crews to deploy and retrieve, reducing manual handling risks and saving valuable time on each setup. The design also considers versatility; a single, well-designed crane outrigger pad can be used effectively on a variety of surfaces, from soft turf to paved parking lots.

Furthermore, the right design protects more than just the crane; it protects the job site. By distributing the load effectively, it prevents expensive damage to existing infrastructure like roads, sidewalks, and underground utilities. Investing in a correctly specified and designed crane outrigger pad is a fundamental safety protocol. It is the indispensable final link in the chain of safe crane operation, ensuring that the immense power of the machine is balanced by an equal measure of stability and control.

Previous: What are the primary advantages of using HDPE plastic sheets? Next: Why Choose HDPE Marine Board for Outdoor Cabinets?

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom