Peliou New Materials Technology Co.,LTD

At the core of efficient logistics operations, the semi-trailer saddle plate serves as the critical component connecting the tractor unit to the trailer. Its performance directly impacts vehicle safety, operational costs, and overall efficiency. Tradition

What is Ultra-High Molecular Weight Polyethylene (UHMW-PE)? UHMW-PE is a linear-structured thermoplastic engineering polymer with a molecular weight exceeding 1.5 million—tens of times higher than standard polyethylene. This unique molecular structure endows it with exceptional properties:

Exceptional Wear Resistance: 7 times more wear-resistant than carbon steel, 10 times more than stainless steel, and 6 times more than nylon

Ultra-low friction coefficient: Self-lubricating properties reduce friction resistance by over 60%

Exceptional impact resistance: Maintains toughness even in extreme temperatures from -200°C to +80°C

Superior chemical stability: Resists acid and alkali corrosion, suitable for harsh environments

Weight advantage: Density of only 0.96 g/cm³, 85% lighter than metal

Five Core Advantages of UHMW-PE Wear Plates

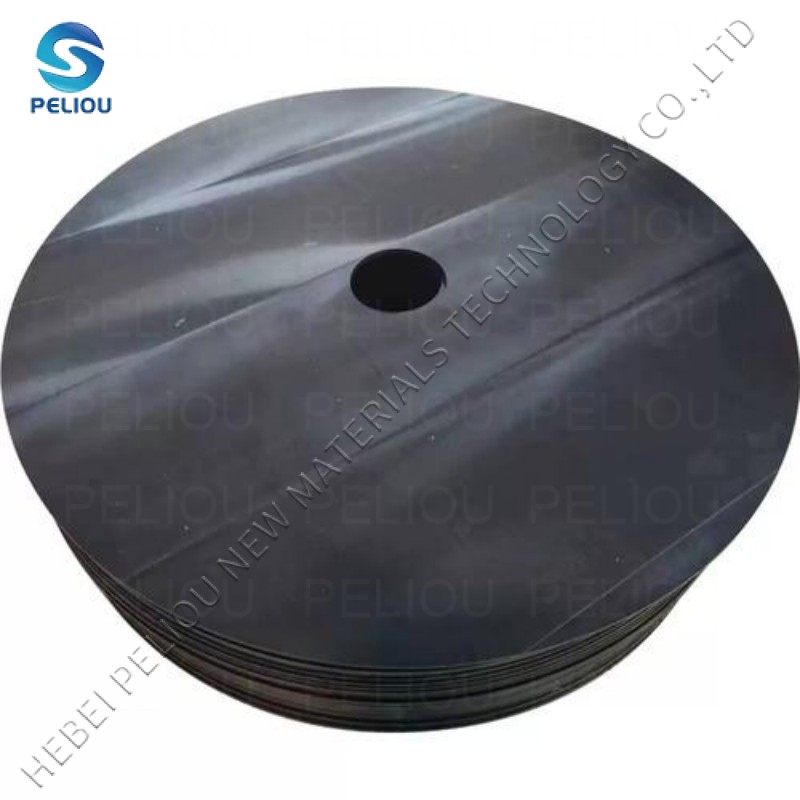

1. Ultimate wear resistance significantly extends replacement cycles. Peliou's UHMW-PE wear discs feature a specialized formulation and processing technique, achieving surface hardness exceeding HRC 65. Their wear resistance is 8-10 times that of traditional manganese steel discs. Field data shows that under identical transport conditions, traditional metal discs have an average lifespan of just 8 months, while UHMW-PE wear discs last over 30 months—directly reducing replacement frequency by 70%.

2. Self-Lubricating Design, Significantly Reducing Maintenance Costs The inherent self-lubricating properties of UHMW-PE material enable the wear plates to maintain smooth, low-friction operation with minimal or no additional lubricant. This translates to: - Over 80% annual savings in lubricant costs - Elimination of premature wear caused by insufficient lubrication - Prevention of lubricant contamination to cargo and the environment

3. Lightweight construction enhances fuel efficiency Traditional steel wear discs weigh 15-20 kg each, while UHMW-PE wear discs weigh only 2-3 kg. Based on an annual vehicle mileage of 150,000 km, the weight reduction from wear discs alone saves approximately 300-500 liters of fuel per vehicle annually, reducing CO₂ emissions by nearly 1 ton.

4. Exceptional Impact Resistance for Harsh Conditions Through molecular chain optimization and specialized reinforcement processes, Peliou's UHMW-PE wear plates achieve impact strength of 150KJ/m². They maintain outstanding toughness even at -40°C, perfectly adapting to China's diverse transportation environments characterized by significant temperature variations and complex road conditions.

5. Safe and Quiet Operation for Enhanced Driving Experience Eliminates the sharp metallic friction noise, reducing cab noise levels by 3-5 decibels to create a more comfortable working environment for drivers. Stable friction characteristics also minimize abnormal saddle vibrations, improving overall vehicle stability.

Compatibility and Installation Guide

Peliou offers customization services for various UHMW-PE wear plates, compatible with major domestic and international fifth-wheel models including JOST, SAF-HOLLAND, and FUWA.

Installation is simple and quick: Clean the saddle slide plate surface, remove the old wear plate (if applicable), align with mounting holes, and secure the UHMW-PE wear plate. No special lubrication is required for immediate use. Installation takes only 15-20 minutes and can be completed rapidly by maintenance personnel without specialized tools.

Contact Peliou's sales team for a customized quote and tailored solutions. Empower your fleet with advanced material technology and drive toward a more efficient, cost-effective transportation future.

Previous: Back List Next: UHMW Upper Cable Clamp

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom